DOE and parameter optimization :

We conduct Design of Experiments (DOE) and parameter optimization using the Latin Hypercube Sampling (LHS) method to identify and control the key factors influencing thermal performance, noise, weight, reliability, and cost. Here’s an explanation of how DOE and parameter optimization using LHS can be applied in this context:

- Design of Experiments (DOE) with Latin Hypercube Sampling (LHS):

– DOE: DOE is a systematic approach that involves designing and conducting a series of experiments to gather data and analyze the effects of different factors or variables on the response or outcome of interest. In thermal TLAs, factors can include design variables related to heat dissipation mechanisms, material choices, component placement, insulation, airflow management, and more.

– LHS: LHS is a sampling strategy used to select factor levels in a more representative and evenly distributed manner. It ensures that the design space is adequately explored by randomly selecting one level from each factor’s range without repetition. LHS provides a more comprehensive coverage of the factors and reduces bias in the experimental design.

- Identifying Key Factors:

– Define Key Factors: Identify the factors that significantly influence thermal performance, noise, weight, reliability, and cost in the TLA design. These factors can be determined based on engineering knowledge, literature review, or preliminary studies.

– Determine Factor Levels: Determine the range and number of levels for each key factor. For example, the material factor can have different options like aluminum, copper, or composite, while the airflow rate factor can have low, medium, and high levels.

- Experimental Design:

– LHS Sampling: Use LHS to generate a set of unique and representative combinations of factor levels. LHS ensures that the design space is evenly sampled, allowing for a more thorough exploration of the factors and their interactions.

– Conduct Experiments: With the LHS-generated experimental design, perform experiments or simulations to collect data on thermal performance, noise levels, weight, reliability, and cost for each unique combination of factor levels. Measure or calculate the responses based on the defined metrics and objectives.

- Response Analysis and Modeling:

– Analyze Data: Analyze the collected response data to understand the relationships between the factors and the responses. Statistical analysis techniques, such as regression analysis or analysis of variance (ANOVA), can help determine the significance of each factor and their interactions.

– Develop Models: Develop mathematical models or response surfaces to represent the relationships between the factors and the responses. These models provide insights into the influence of each factor on thermal performance, noise, weight, reliability, and cost.

- Parameter Optimization:

– Define Objectives and Constraints: Define the optimization objectives, such as maximizing thermal performance, minimizing noise levels, optimizing weight, enhancing reliability, and minimizing cost. Consider constraints such as maximum weight limit, reliability requirements, and cost limitations.

- Sensitivity Analysis:

– Sensitivity analysis can be performed to assess the impact of uncertainty or variations in the factors on thermal performance, noise, weight, reliability, and cost. It helps in understanding the robustness of the optimized design and identifying critical factors that require closer control or consideration.

By combining DOE with LHS and parameter optimization techniques, we systematically analyze and optimize the design factors affecting thermal performance, noise, weight, reliability, and cost. This approach allows for a more representative sampling, identifies the key factors, and facilitates the discovery of optimal factor settings. Ultimately, it enables the creation of highly efficient.

Latest Post

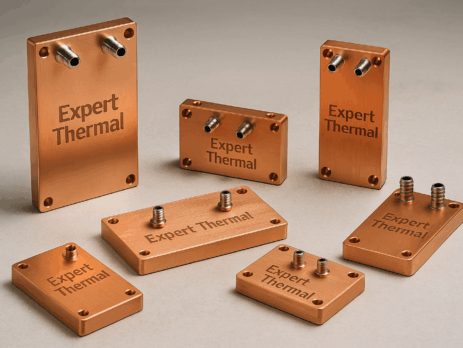

Cold Plate Cooling Systems: Design, Optimization, and Application in High Density Electronics

Team Expert Thermal2025-07-21T17:35:47+00:00...

Thermal Interface Materials (TIMs): The Backbone of Efficient Thermal Management

Team Expert Thermal2025-03-13T06:41:30+00:00...

Liquid Cooling for Data Centers: The Key to Unleashing AI and High-Density Computing

Team Expert Thermal2024-12-13T15:28:17+00:00...

The Importance of Thermal Design and Analysis in Product Development: A Key to Success

Team Expert Thermal2024-10-04T03:56:53+00:00...

Innovative Cooling Strategies for AI and HPC: Ensuring Efficiency and Sustainability

Team Expert Thermal2024-09-04T10:53:23+00:00...

The Rise of AI and the Need for Efficient Thermal Management

Team Expert Thermal2024-08-22T13:38:54+00:00...

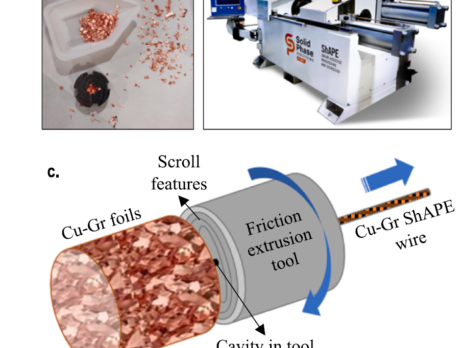

ShAPE-ing the Future: A New Technique for High-Performance Copper Composites

Team Expert Thermal2024-01-15T11:11:21+00:00...

Contact us

- Address: 7091 Kindra Hill Dr., San Jose, CA 95120

- Phone: +1 (408) 641-1398

- Email:sales@expertthermal.com